MANUFACTURING

creating superior products generates superior results

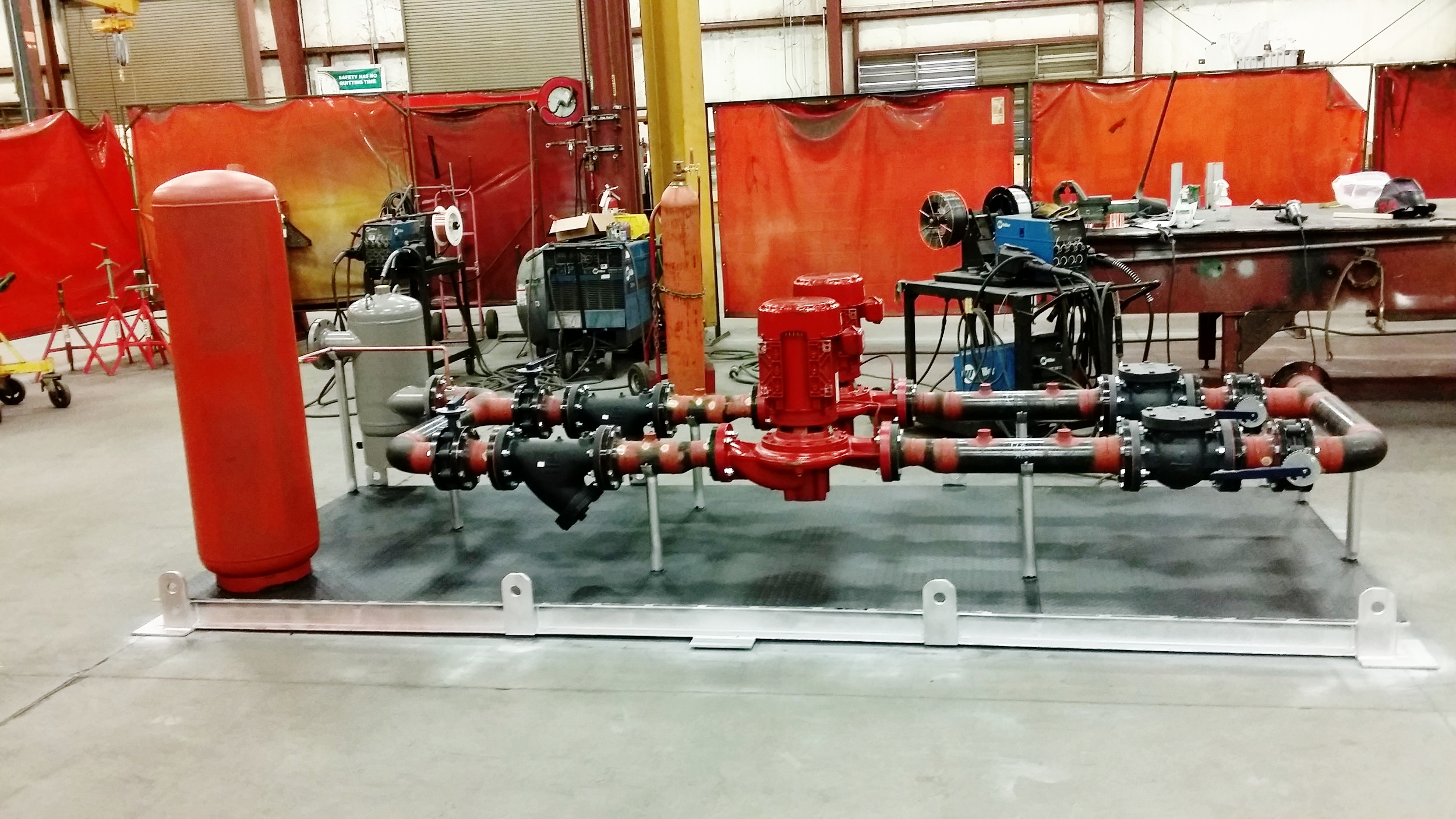

Our nearly 90,000-square foot prefabrication facility is populated with expert tradesmen with extensive experience in fabrication and assembly of ductwork, plumbing, and piping systems using many metals and plastics. In addition, we fabricate structural support and equipment skids. Shop drawings for fabrication are prepared and quality checked directly from our coordinated BIM models.

Our manufacturing activities occur in a safe, quality controlled environment allowing us to maximize field production and meet the most demanding schedules and sequences.

Material management and logistics, supported by an in-house transportation fleet, ensuring on-time timely delivery to project sites.